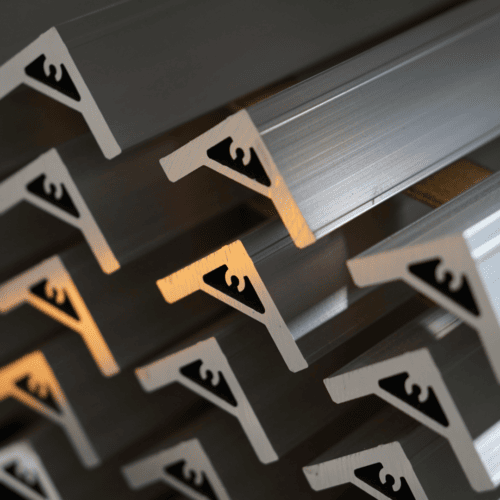

Plastic Extrusion Manufacturing Services- Flexible Profiles

Our extrusion services can help create profiles from resilient materials that have several applications including outdoor furniture, marine equipment, door jambs, and many more.

We use advanced technologies to create precise shapes and custom sizes that fit perfectly, plus our color and additional upgrades like UV protection can improve aesthetics and help guarantee long-term performance.

Contact us today to learn more about our existing profiles or find out how to get custom extrusion services designed exclusively for your application.

Types of Extrusion Services We Offer

Our extrusion process takes your raw material and uses a shaped die to create the desired shape. We can perform hot extrusion if the material requires it, then use a state-of-the-art cooling system to solidify the piece as well as cutting and finishing equipment to finalize the part.

Here are some of the types of extrusion we offer:

Rigid and Flexible Profiles

Polymer profiles are used in window sills and door jambs, as well as in marine equipment and other tools that require hermetic closures. Our technicians and engineers can design a wide range of rigid profiles that help guarantee safety even under extreme conditions.

Likewise, our team can also design and manufacture flexible profiles that slightly give in when exposed to pressure, but recover quickly from the impact.

Customization Options for Your Specific Needs

Do you have specific requirements, like impermeability, opaqueness, and reflective properties? At Master Tool, we can fully customize your profiles to ensure they’re:

- Non-toxic and water-proof

- Non-magnetic and non-sparking

- Malleable and easy to work with

- Reflective, flame-retardant, and UV-resistant

- Painted and finished to your requirements

Die-Making for Custom Parts

If none of our existing dies fit your requirements, we can create a custom die that we’ll only use to manufacture your profiles. Our team of engineers can work with you to ensure that the part and material match your specifications, as well as consult on improvements and enhancements that can improve your products.

Industry-Specific Applications

Are you in the marine industry, aerospace, or a similar technical field that has to meet security standards and industry requirements? Contact us today to learn more about our comprehensive solutions.

What Sets Master Tool Apart from the Rest

Expertly Crafted Components

At Master Tool, we have a standing commitment to delivering the best parts in order to help our clients build high-quality products. Our team of professionals has extensive experience creating custom dies, helping clients improve their designs, and working at a fast pace while still adhering to strict safety protocols.

Our Availability is Unmatched

We pride ourselves on being here for our clients whenever they need us. Whether you need guidance in the early design stages, input during the manufacturing process, or expert feedback while prototyping, our team of experts is here to help.

Flexible and Dynamic

At Master Tool, we understand that every project is unique, which is why we offer flexible and dynamic extrusion solutions. Whether you need rigid profiles for structural integrity or flexible ones that adapt to movement and pressure, we can fine-tune our process to match your exact requirements.

Materials that Last

Durability is at the core of everything we produce. We source high-quality polymers and materials designed to withstand harsh environments, extreme temperatures, and heavy use. Whether your application requires impact-resistant profiles, weatherproof coatings, or UV protection, our materials are engineered for long-term performance.

Non-Toxic, Waterproof Materials

Safety and reliability go hand in hand, which is why our materials are carefully selected to meet the highest industry standards. Our non-toxic and waterproof profiles are ideal for applications in the marine, medical, and food-grade industries where exposure to moisture and contaminants is a concern.

A Commitment to Customer Experience

From concept to final product, our goal is to make the extrusion process as smooth and efficient as possible for our clients. Our team of engineers and technicians works closely with you to understand your needs, provide expert recommendations, and deliver precise, high-quality solutions.

Contact Master Tool Today

Our flexible PVC profiles have countless applications, including outdoor patios, marine equipment, and other high-intensity conditions. We provide comprehensive quality extrusion services to create rigid and flexible parts made of polymers in order to fit your specific needs. Plus, these can be customized with colors and additional additives based on your requirements.

You can choose from a wide collection of profiles and materials, or we can create a custom die specifically for your application. Contact us today to find out more about our custom extrusion services. Our team of technicians and engineers will be glad to help.

Have any questions about your upcoming project?

Contact us and see how we can meet your project requirements.