When it comes to injection molding, there isn’t a single “best” resin, and the right choice depends on your part’s requirements. Part strength, durability, appearance, safety, and even how quickly and cost-effectively the part can be molded are all factors that can help determine the right material for your project. For example, Nylon may be chosen when high strength and hardness are required, while TPE/TPU is ideal for overmolding applications where flexibility and a soft-touch feel are needed. On top of that, some resins mold easier than others, which impacts tolerances, surface finish, and production efficiency.

Below is a practical guide you can use to narrow down material options and make a confident decision.

Material Cheat Sheet: Plastics for Injection Molding

| Material | Key Traits | Critical Factors | Standard uses |

| ABS | Tough, stiff, easy to finish, dimensionally stable | Poor UV or chemical resistance vs. PC. Moderate heat. | Enclosures, housings, handhelds. |

| PC (Polycarbonate) | High impact strength. Naturally transparent. Good heat resistance. | Stress cracking with some chemicals. Drying needed. | Lenses, guards, lighting, electronics. |

| PP (Polypropylene) | Excellent chemical resistance. Low density. | Shrink and warp risk. Brittle in cold environments | Caps, packaging, consumer goods. |

| PA 6/66 (Nylon) | Strong and wear resistant. Good fatigue. Higher heat than PP or PE. | Moisture uptake changes dimensions and properties. | Gears, clips, mechanical parts. |

| POM (Acetal) | Low friction. High stiffness. Excellent dimensional stability. | Fuel and solvent sensitivity in some grades. Thermal expansion. | Gears, latches, bearings. |

| PE (HDPE) | Tough, impact and chemical resistant. Lightweight. | High shrink. Lower stiffness and finish vs. ABS/PC. | Containers, totes, cases, tanks. |

| TPE/TPU | Elastomeric feel. Overmolding. Good abrasion (TPU). | Compression set. Temperature limits depend on the family. | Grips, seals, gaskets. |

Resin Families

Thermoplastics vs. Thermosets

Most injection-molded parts are made from thermoplastics. These resins soften when heated, which means they can be remelted, reshaped, and in many cases recycled.

Thermosets, in contrast, undergo a chemical reaction during curing that creates permanent cross-links in the material. Once set, they cannot be melted to be reformed. Thermosets are typically chosen for applications that demand high heat resistance and long-term dimensional stability, but they offer little flexibility for reprocessing.

Thermoplastics are further divided into amorphous and semi-crystalline families:

Amorphous resins (ABS, Polycarbonate) have a random molecular structure. They usually shrink less and more predictably during molding, which helps produce parts with consistent dimensions, tight tolerances, and smooth surface finishes.

Semi-crystalline resins (Polypropylene, Nylon, Acetal) have highly ordered molecular regions. They typically shrink more, and the shrinkage can vary depending on flow direction. This can lead to warpage if processing isn’t carefully controlled.

For context, ABS generally shrinks about 0.4–0.7%, while polypropylene can shrink as much as 1.0–2.5%. These differences directly influence how molds are designed and how parts must be engineered to ensure a good fit and function.

Key Factors to Decide Early

- Mechanical Needs – Impact strength, stiffness, fatigue resistance.

- Thermal Needs – Service temperature, heat deflection, Vicat limits.

- Chemical/UV Resistance – Compatibility with cleaners, solvents, or outdoor use.

- Aesthetics – Color, transparency, and texture.

- Regulatory Requirements – UL flame rating, ISO 10993 biocompatibility, etc.

- Manufacturability – Flow, shrinkage, draft angles, warpage.

- Cost and Supply – Material price, cycle time, additives, and lead time.

At Master Tool Company, we take a well-rounded approach to analyzing these factors before recommending the most suitable material for a project.

Design & Tooling Notes

Material selection and part design must be considered together. The properties of the resin directly influence how a part should be designed, and design decisions affect how the resin behaves in molding. Some key guidelines to keep in mind are:

- Wall Thickness

- Draft Angles

- Shrinkage

- Gates and Cooling

- Surface Appearance.

- Additives and Fillers

At Master Tool Company, we understand that a part’s design is just as important as the material it’s made from. That’s why we take a dual-sided approach, optimizing both the material and the design to ensure the best results for your part.

Cost Considerations

The price per pound of resin is only one piece of the puzzle. Many other factors drive the real cost of a molded part:

- Cooling Time vs. Wall Thickness

- Regrind Usage

- Additives and Fillers

- Supply and Lead Time

While the cost of a part’s material is an important factor in selecting the right option, we don’t let it be the sole driver when finalizing material choices. Instead, we consider all the factors mentioned earlier in our decision-making process.

Work With a Trusted Partner

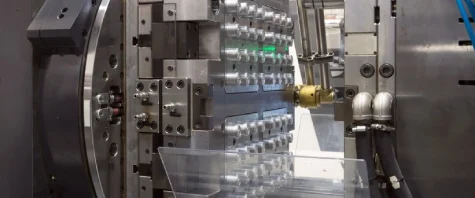

At Master Tool Company, we turn ideas into production-ready parts. With presses ranging from 30 to 500 tons, we have the versatility to tackle projects of any scale. Our team works with a wide variety of resins, including ABS, Nylon, PC, PP, PE, Acetal, and TPU/TPE, to deliver the right balance of performance and value.

We don’t just mold parts. We deliver solutions. From overmolding and insert molding to multi-cavity tooling, our expertise ensures you get parts that are precise, durable, and efficient to produce. And with in-house engineering, CAD/CAM, and prototyping, we help you shorten lead times and avoid costly design missteps.

Have a project in mind? Let us recommend the best material and provide a file review to make sure your design is optimized for quality, cost, and speed to market.